Step 1: Setup of the Silicon model system

The first task in this tutorial is to build the model system we will use for both the classical and QM/MM simulations. We will use an approximately 2D model system in the thin strip geometry

1.1 Building the bulk unit cell (30 minutes)

Import the relevant modules and functions

We start by importing all the functions we will need. Create a new

script named make_crack.py and add the following lines:

from ase.lattice import bulk

from ase.lattice.cubic import Diamond

from ase.constraints import FixAtoms

import ase.units as units

from quippy import set_fortran_indexing

from quippy.potential import Potential, Minim

from quippy.elasticity import youngs_modulus, poisson_ratio

from quippy.io import write

from quippy.crack import (print_crack_system,

G_to_strain,

thin_strip_displacement_y,

find_crack_tip_stress_field)

Note that some routines come from ASE and others from quippy. We will use ASE for basic atomic manipulations, and quippy to provide the interatomic potentials plus some special purpose functionality.

Note

For interactive use, it is convenient to import everything from the

entire quippy package with from qlab import * as described

in the Practical considerations section. We chose not to do that in these scripts to

make it clear where each function we are using is defined, and to make it easier

to look them up in the online documentation.

Definition of the simulation parameters

Let’s first define the parameters needed to construct our model system. There are three possible crack systems. For now, we will use the first (uncommented) one, \((111)[01\bar{1}]\), which means a crack propagating on the \((111)\) cleavage plane (the lowest surface energy of all silicon surfaces) with the crack front along the \([01\bar{1}]\) direction:

# System 1. (111)[0-11]

crack_direction = (-2, 1, 1) # Miller index of x-axis

cleavage_plane = (1, 1, 1) # Miller index of y-axis

crack_front = (0, 1, -1) # Miller index of z-axis

# # System 2. (110)[001]

# crack_direction = (1,-1,0)

# cleavage_plane = (1,1,0)

# crack_front = (0,0,1)

# # System 3. (110)[1-10]

# crack_direction = (0,0,-1)

# cleavage_plane = (1,1,0)

# crack_front = (1,-1,0)

If you have time later, you can come back to this point and change to one of the other fracture systems. Next we need various geometric parameters:

width = 200.0*units.Ang # Width of crack slab

height = 100.0*units.Ang # Height of crack slab

vacuum = 100.0*units.Ang # Amount of vacuum around slab

crack_seed_length = 40.0*units.Ang # Length of seed crack

strain_ramp_length = 30.0*units.Ang # Distance over which strain is ramped up

initial_G = 5.0*(units.J/units.m**2) # Initial energy flow to crack tip

Note the explicit unit conversion: some of this is unnecessary as we

are using the ase.units module where Ang = eV =

1. The energy release rate initial_G is given in the

widely used units of J/m2.

Next we define some parameters related to the classical interatomic potential:

relax_fmax = 0.025*units.eV/units.Ang # Maximum force criteria

param_file = 'params.xml' # XML file containing

# interatomic potential parameters

mm_init_args = 'IP SW' # Initialisation arguments

# for the classical potential

And finally the output file:

output_file = 'crack.xyz' # File to which structure will be written

You should download the params.xml file, which contains

the parameters for the SW potential (and also for DFTB, needed for

Step 3: LOTF hybrid MD simulation of fracture in Si)

Finding the equilibrium lattice constant for Si

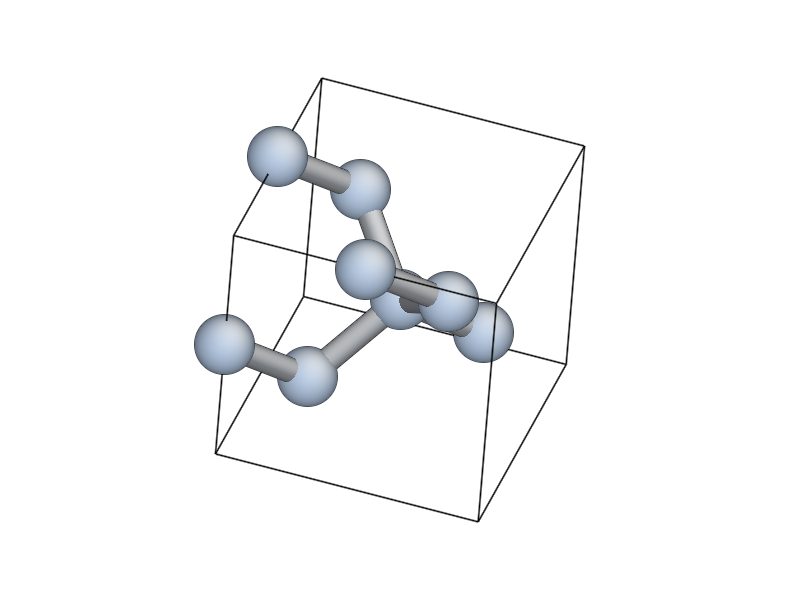

To find the Si equilibrium lattice constant a0 with the SW potential,

let’s first build the 8-atom diamond cubic cell for silicon, with an initial

guess at lattice constant of 5.44 A. This can be done using the

bulk() function from the ase.structure module:

si_bulk = ... # Build the 8-atom diamond cubic cell for Si

The variable si_bulk is an Atoms object. It

has various attributes and methods that will be introduced as necessary

during this tutorial.

Once you have created your si_bulk object, run the make_crack.py

script from within ipython with the run command. Providing you

have imported everything from the qlab module, will then be

able to interactively visualise the Si unit cell with the

view() function from the qlab module, which you

should type in at the ipython prompt:

In [5]: view(si_bulk)

This will pop up an AtomEye [Li2003] window showing the 8-atom

silicon cell, with the unit cell boundary drawn with a thick black

line. You can rotate the system with the left mouse button, translate

by holding Control and tracking, or translate within the periodic

boundaries by holding Shift and dragging. Zoom in and out by

dragging with the right mouse button (or scroll wheel, if you have

one). Press b to toggle the display of bonds. For more help on

AtomEye see its web page or the documentation

for the qlab and atomeye modules.

Now, we initialise the Stillinger-Weber (SW) classical interatomic

potential using quippy’s Potential class

mm_pot = Potential('IP SW', param_filename='params.xml')

The equilibrium lattice constant a0 can now be found by minimising the

cell degrees of freedom with respect to the virial tensor calculated by the

SW potential. First, we need to attach a calculator (i.e. the SW

potential, mm_pot we just created) to the si_bulk object,

using the method set_calculator():

si_bulk. ... # Attach the SW potential to si_bulk

This means that subsequent requests to calculate energy or forces of si_bulk will be performed using our SW potential.

The minimisation can now be carried out by making a

Minim class from the si_bulk Atoms,

requesting that both atomic positions and cell degrees of freedom

should be relaxed. Then run the minimisation until the maximum force

is below fmax=1e-2, using the run()

method

minim = ... # Initialise the minimiser from si_bulk

print('Minimising bulk unit cell')

minim. ... # Run the minimisation

The lattice constant a0 can be easily obtained from the relaxed

lattice vectors using the cell() attribute of

the si_bulk object, which returns a \(3 \times 3\) matrix

containing the lattice vectors as rows in Cartesian coordinates,

i.e. si_bulk.cell[0,0] is the x coordinate of the first lattice

vector.

a0 = ... # Get the lattice constant

print('Lattice constant %.3f A\n' % a0)

As a check, you should find a value for a0 of around 5.431 A.

Once you have obtained a0, you should replace the si_bulk object with a new bulk cell using this lattice constant, so that the off-diagonal components of the lattice are exactly zero:

si_bulk = ... # Make a new 8-atom bulk cell with correct a0

si_bulk. ... # re-attach the SW potential as a calculator

Milestone 1.1

At this point your script should look something like make_crack_1.py.

1.2 Calculation of elastic and surface properties of silicon (30 minutes)

Calculation of the Young’s modulus and the Poisson ratio

Following the discussion above section, we need to

calculate some elastic properties of our model silicon. To calculate the Young’s

modulus E along the direction perpendicular to the cleavage plane, and the

Poisson ratio \(\nu\) in the \(xy\) plane, we need the \(6 \times

6\) matrix of the elastic constants \(C_{ij}\). This matrix c can be

calculated using the get_elastic_constants()

method of the mm_pot Potential object.

c = mm_pot. ... # Get the 6x6 C_ij matrix

print('Elastic constants (GPa):')

print((c / units.GPa).round(0))

print('')

Here, the GPa constant from the ase.units module module is used to

convert from pressure units of eV/A3 into GPa.

The Young’s modulus E and the Poisson ratio nu can now be calculated,

given c, the cleavage_plane and the crack_direction (defined in the

parameters section above), using the functions

youngs_modulus() and

poisson_ratio() from the

quippy.elasticity module.

E = ... # Get E

print('Young\'s modulus %.1f GPa' % (E / units.GPa))

nu = ... # Get nu

print('Poisson ratio % .3f\n' % nu)

As a check, for the \((111)[01\bar{1}]\) crack system, you should get a Young’s modulus of 142.8 GPa and a Poisson ratio of 0.265.

Calculation of the surface energy of the cleavage plane

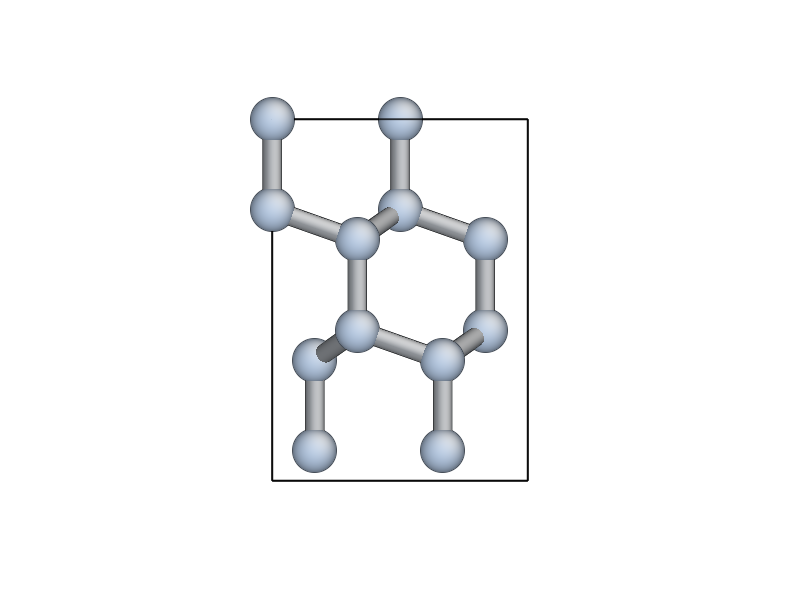

To calculate the surface energy per unit area gamma of the cleavage_plane, we build a Si slab unit cell aligned with the requested crystallographic orientation. The orientation of the crack system can be printed using the following command:

print_crack_system(crack_direction, cleavage_plane, crack_front)

The new unit slab can be obtained using the

ase.lattice.cubic.Diamond

from the ase.lattice module, which is used as follows:

unit_slab = Diamond(directions=[crack_direction,

cleavage_plane,

crack_front],

size=(1, 1, 1),

symbol='Si',

pbc=True,

latticeconstant=a0)

print('Unit slab with %d atoms per unit cell:' % len(unit_slab))

print(unit_slab.cell)

print('')

You can visualise the new cell with view(unit_slab) (type this at

the ipython prompt after running the script as it is so far, don’t

add it to the script file):

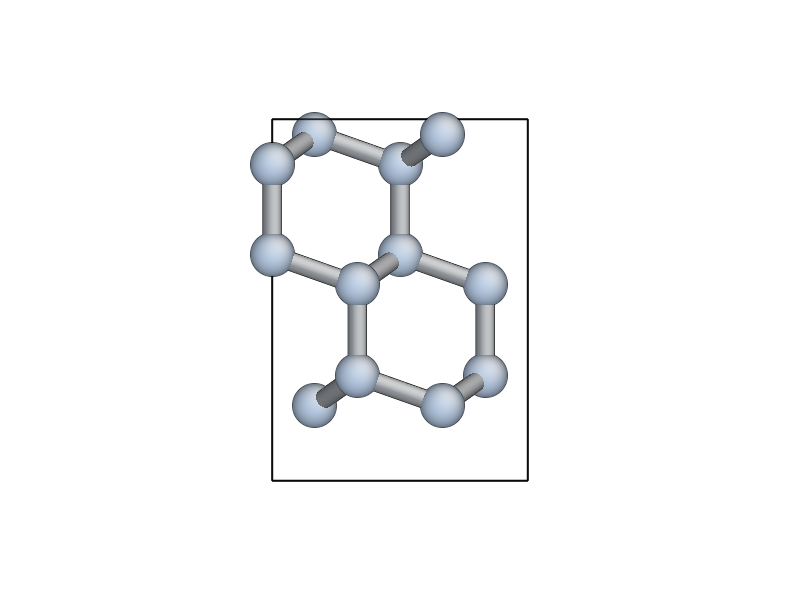

We now shift the unit_slab vertically so that we will open up a surface along a \((111)\) glide plane, cutting vertically aligned bonds (see e.g. this image). This choice gives the lowest energy surface. We then map the positions back into the unit cell:

unit_slab.positions[:, 1] += (unit_slab.positions[1, 1] -

unit_slab.positions[0, 1]) / 2.0

unit_slab.set_scaled_positions(unit_slab.get_scaled_positions())

The positions is a (N,3) array containing

the Cartesian coordinates of the atoms, and

set_scaled_positions() and

get_scaled_positions() are necessary to ensure

all the atoms are mapped back inside the unit cell before we open

up a surface. This is the result of applying the shift (do another

view(unit_slab) to update your AtomEye viewer).

Note how the top and bottom layers now correspond to \((111)\) glide planes, so that the cell boundary now corresponds to a shuffle plane as required.

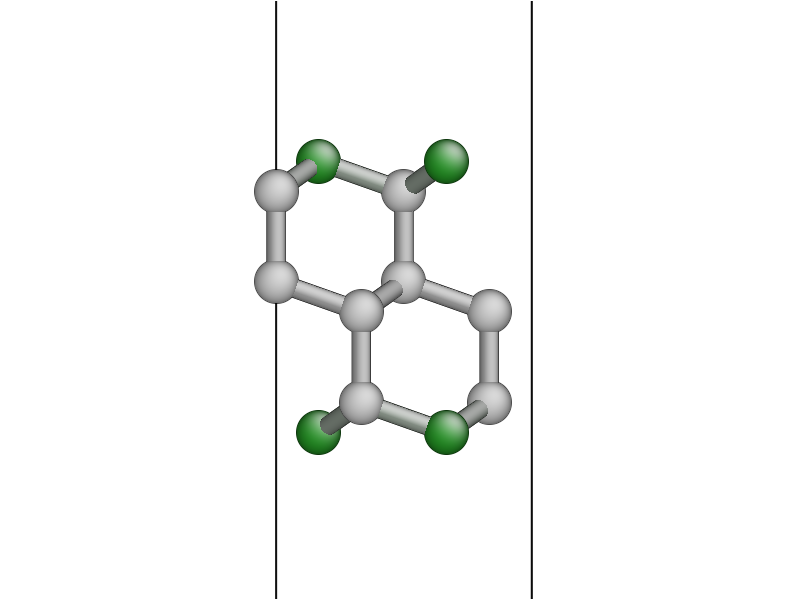

We now make a copy of the unit_slab and create a surface unit cell

with surfaces parallel to the cleavage_plane. We can use the

ase.atoms.Atoms.center() method which, besides centring the

atoms in the unit cell, allows some vacuum to be added on both sides

of the slab along a specified axis (use axis=0 for the x-axis,

or axis=1 for the y-axis, etc.). The amount of vacuum you add is

not critical, but could be taken from the vacuum parameter in the

parameters section above:

surface = unit_slab.copy()

surface. ... # Add vacuum along y axis

You should get a surface unit cell which looks something like this:

Here, the atoms have been coloured by coordination by pressing the k key. The green atoms on the surfaces are three-fold coordinated.

Now that we have both the bulk unit slab and the surface unit cell,

the surface energy gamma for the cleavage plane can be calculated

using the SW potential. Once a calculator (e.g. mm_pot) is attached

to an Atoms object, the potential energy of the

atomic system can be calculated with

get_potential_energy(). It is useful to know

that the number of atoms in an Atoms object can be obtained by the

list-method len (e.g. len(si_bulk) gives the number of atoms in

si_bulk), and that the volume of a cell can be calculated with

get_volume():

surface. ... # Attach SW potential to surface atoms

E_surf = ... # Get potential energy of surface system

E_per_atom_bulk = ... # Get potential energy per atom for bulk slab

area = ... # Calculate surface area using volume and cell

gamma = ... # Calculate surface energy

print('Surface energy of %s surface %.4f J/m^2\n' %

(cleavage_plane, gamma / (units.J / units.m ** 2)))

As a check, you should obtain \(\gamma_{(111)}\) = 1.36 J/m2. You may want to verify that this result is converged

with respect to the number of layers in the system (note the cutoff

distance of the SW potential, which you can obtain with

mm_pot.cutoff(), is about 3.93 A, just beyond the second neighbour

distance).

Milestone 1.2

At this point your script should look something like make_crack_2.py

1.3 Setup of the crack slab supercell (30 minutes)

Replicating the unit cell to form a slab supercell

Now, we have all the ingredients needed to build the full crack slab system and to apply the requested strain field.

We start by building the full slab system. First, we need to find the number

of unit_slab cells along x and y that approximately match width and

height (see parameters section).

Note that the python function int() can be used to

convert a floating point number into an integer, truncating towards zero:

nx = ... # Find number of unit_slab cells along x

ny = ... # Find number of unit_slab cells along y

To make sure that the slab is centered on a bond along the y direction, the number of units cell in this direction, ny, must be even:

if ny % 2 == 1:

ny += 1

The crack supercell is now simply obtained by replicating unit_slab \(nx \times ny \times 1\) times along the three axes:

crack_slab = unit_slab * (nx, ny, 1)

As we did before for the surface system, vacuum has to be introduced along

the x and y axes (Hint: use the center()

method twice)

crack_slab. ... # Add vacuum along x

crack_slab. ... # Add vacuum along y

The crack_slab is now centered on the origin in the xy plane to make it simpler to apply strain:

crack_slab.positions[:, 0] -= crack_slab.positions[:, 0].mean()

crack_slab.positions[:, 1] -= crack_slab.positions[:, 1].mean()

and its original width and height values are saved, and will later be used to measure the strain:

orig_width = (crack_slab.positions[:, 0].max() -

crack_slab.positions[:, 0].min())

orig_height = (crack_slab.positions[:, 1].max() -

crack_slab.positions[:, 1].min())

print(('Made slab with %d atoms, original width and height: %.1f x %.1f A^2' %

(len(crack_slab), orig_width, orig_height)))

The original y coordinates of the top and bottom of the slab and the original x coordinates of the left and right surfaces are also saved:

top = crack_slab.positions[:, 1].max()

bottom = crack_slab.positions[:, 1].min()

left = crack_slab.positions[:, 0].min()

right = crack_slab.positions[:, 0].max()

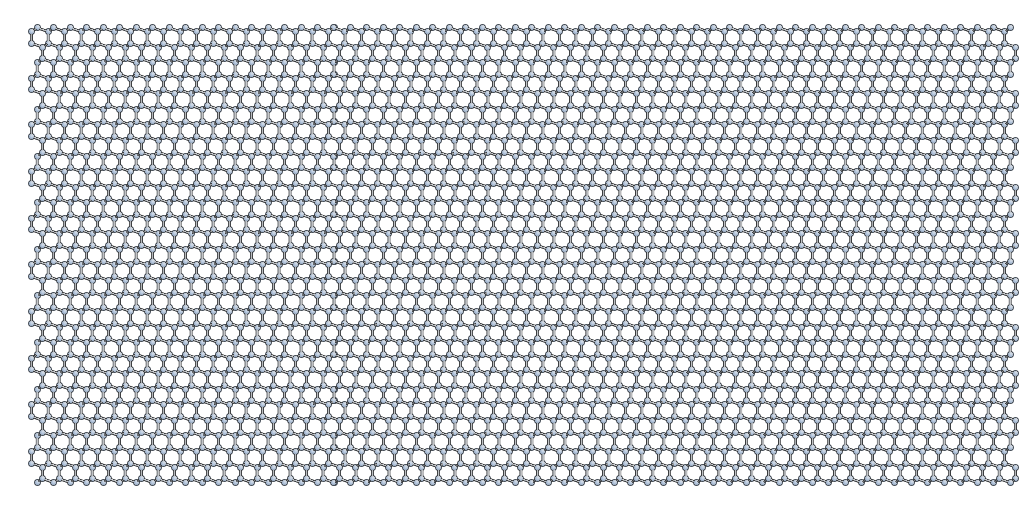

At this point, your crack_slab should look something like this:

Setting constraints to fix the edge atoms

During the MD simulations, the positions of the top and bottom rows of atoms will be kept fixed. More precisely, these rows of atoms will only be moved rigidly when the strain is applied and will not move in response to forces from the interatomic potential (see the discussion of the thin strip geometry above). To do this, we initialise a fixed_mask array that is True for each atom whose position needs to be fixed, and False otherwise:

fixed_mask = ((abs(crack_slab.positions[:, 1] - top) < 1.0) |

(abs(crack_slab.positions[:, 1] - bottom) < 1.0))

Note that the | operator is shorthand for a logical ‘or’

operation. After re-running the latest version of your script and

executing view(crack_slab), you can colour the atoms by

fixed_mask using the aux_property_coloring() function

aux_property_coloring(fixed_mask)

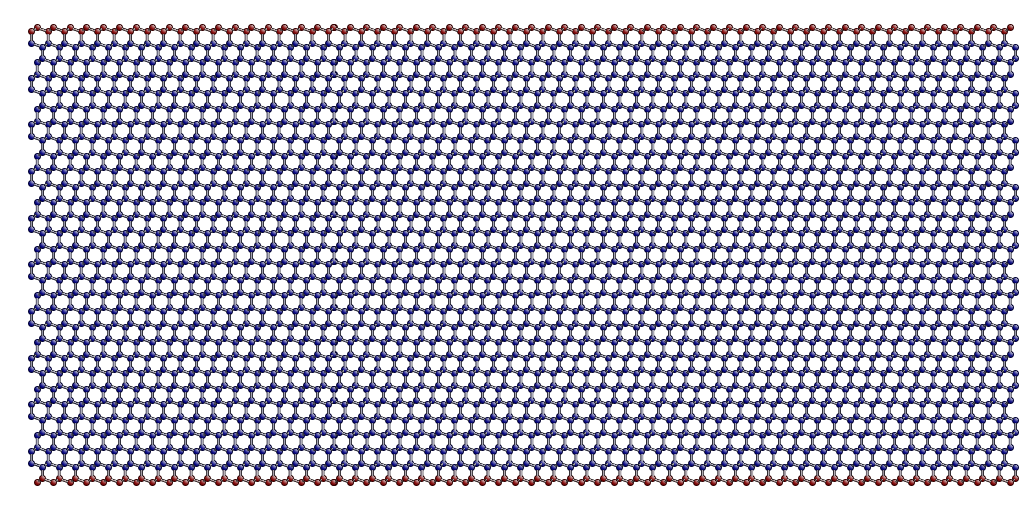

which colours the atoms where fixed_mask is True in red and those where it is False in blue, like this:

Now we can use the FixAtoms class to

fix the positions of the atoms according to the mask fixed_mask, and

then attach the constraint to crack_slab using

set_constraint():

const = ... # Initialise the constraint

crack_slab. ... # Attach the constraint to crack_slab

print('Fixed %d atoms\n' % fixed_mask.sum())

To create the crack seed, we now apply the initial strain ramp. First,

we need to convert the chosen energy release rate initial_G into a

strain. This can be done using the G_to_strain()

function which implements the thin strip equation described

above. The strain is then used to displace

the y coordinate of the atomic positions according to the strain

ramp produced by the thin_strip_displacement_y()

function. Here, the crack_seed_length and the strain_ramp_length

parameters should be used. The objective is that atoms to the left of

left + crack_seed_length should be rigidly shifted vertically, and

those to the right of left + crack_seed_length +

strain_ramp_length should be uniformly strained, with a transition

region in between.

strain = ... # Convert G into strain

crack_slab.positions[:, 1] += ... # update the atoms positions along y

print('Applied initial load: strain=%.4f, G=%.2f J/m^2' %

(strain, initial_G / (units.J / units.m**2)))

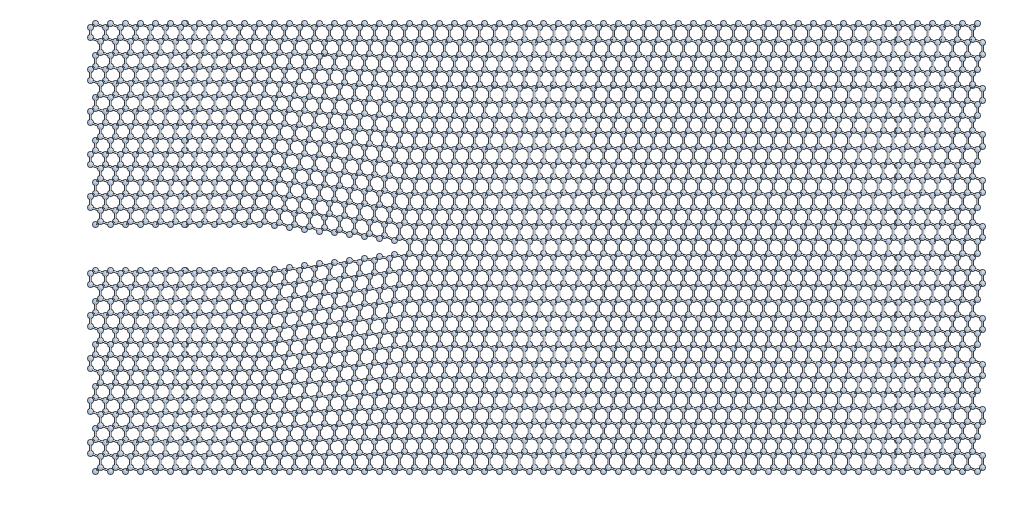

This is the resulting crack slab, for the \((111)\) case:

Relaxation of the crack slab

To obtain a good starting point for the MD, we need to perform an

approximate geometry optimisation of the slab, keeping the top and

bottom rows of atoms fixed. Once again, our mm_pot needs to be

attached to crack_slab and the minimiser

Minim initialised (note that here it does

not make sense to relax the cell since we have vacuum in two

directions). We can then perform the minimisation until the maximum

force is below the relax_fmax defined in the parameters

section:

print('Relaxing slab')

crack_slab. ... # Attach the calculator to crack_slab

minim = ... # Initialise the minimiser

minim. ... # Run the minimisation until forces are relax_fmax

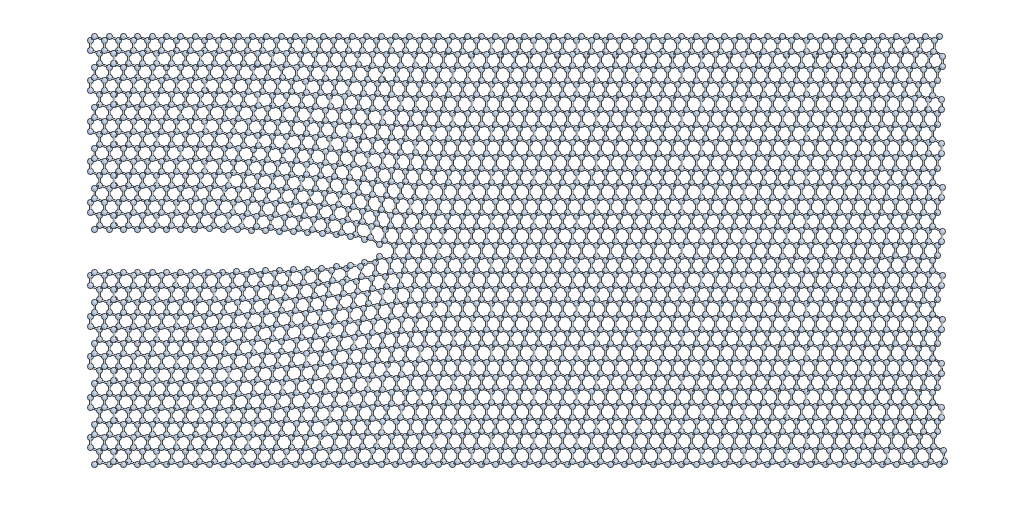

Here’s what your minimised crack slab should look like:

Locating the crack tip

Before starting the next steps, it is useful to find the initial

position of the crack tip. This is provided by the

find_crack_tip_stress_field() function:

crack_pos = find_crack_tip_stress_field(crack_slab, calc=mm_pot)

print 'Found crack tip at position %s' % crack_pos

This function works by fitting the components of the Irwin crack stress field to the per-atom stresses calculated by the classical SW potential, allowing the origin of the analytical stress field to move during the fit. Then, we simply set this point to be the current crack position.

Saving the output file

Finally, we can save all the calculated materials properties inside the

crack_slab Atoms object, before writing it to disk:

crack_slab.info['nneightol'] = 1.30 # set nearest neighbour tolerance

crack_slab.info['LatticeConstant'] = a0

crack_slab.info['C11'] = c[0, 0]

crack_slab.info['C12'] = c[0, 1]

crack_slab.info['C44'] = c[3, 3]

crack_slab.info['YoungsModulus'] = E

crack_slab.info['PoissonRatio_yx'] = nu

crack_slab.info['SurfaceEnergy'] = gamma

crack_slab.info['OrigWidth'] = orig_width

crack_slab.info['OrigHeight'] = orig_height

crack_slab.info['CrackDirection'] = crack_direction

crack_slab.info['CleavagePlane'] = cleavage_plane

crack_slab.info['CrackFront'] = crack_front

crack_slab.info['strain'] = strain

crack_slab.info['G'] = initial_G

crack_slab.info['CrackPos'] = crack_pos

crack_slab.info['is_cracked'] = False

We can save our results, including all the extra properties and information, in extendedxyz in the output_file, whose name is defined in the parameters section:

print('Writing crack slab to file %s' % output_file)

write(output_file, crack_slab)

Milestone 1.3

At this point your final script should look something like

Step 1 solution — make_crack.py, and your XYZ file like crack.xyz.

When you are ready, proceed to Step 2: Classical MD simulation of fracture in Si.