Quasi static fracture simulations

Basic usage

The matscipy.fracture_mechanics.crack module provides classes and functions for setting up and analysing atomistic simulations of fracture.

The same functionality can be accessed in the command line interface, via the matscipy-quasistatic-fracture command.

import numpy as np

import ase.io

import ase.units as units

from ase.build import bulk

from ase.filters import FrechetCellFilter

from ase.optimize.precon import PreconLBFGS

from nglview import show_ase

from matscipy.fracture_mechanics.crack import CubicCrystalCrack

from matscipy.fracture_mechanics.clusters import diamond, set_groups

from matscipy.calculators.manybody.explicit_forms.stillinger_weber import StillingerWeber, Holland_Marder_PRL_80_746_Si

from matscipy.calculators.manybody import Manybody

We first setup a manybody calculator using the “inadvertendly modified Stillinger Weber” (IMSW) parameters, in which the strength of the 3-body potential was (initially accidentally) doubled. This is useful for us here as it gives a brittle fracture response.

calc = Manybody(**StillingerWeber(Holland_Marder_PRL_80_746_Si))

Bulk and Elastic properties

We can use this calculator to find the equilibrium lattice constant for bulk silicon by performing a variable cell relaxation using FrechetCellFilter filter and PreconLBFGS optimizer from ASE. Since the cell is very small the preconditioning does not speed up the calculation; however, it is still useful as this is one of the most robust optimizers and it converges quickly. It is not necessary to use a cubic cell, we do it simply to make the calcualation of the cubic lattice constant alat straight-forward.

el = 'Si' # chemical element

si = bulk(el, cubic=True)

si.calc = calc

ecf = FrechetCellFilter(si)

opt = PreconLBFGS(ecf)

opt.run(fmax=1e-6, smax=1e-6)

PreconLBFGS: 0 21:33:12 -34.692786 0.0000 0.0003

PreconLBFGS: 1 21:33:12 -34.692800 0.0000 0.0000

/home/runner/work/matscipy/matscipy/.venv/lib/python3.12/site-packages/ase/optimize/precon/lbfgs.py:138: UserWarning: The system is likely too small to benefit from the standard preconditioner, hence it is disabled. To re-enable preconditioning, call `PreconLBFGS` by explicitly providing the kwarg `precon`

warnings.warn('The system is likely too small to benefit from '

np.True_

a0 = si.cell[0, 0]

Next we compute the elastic constants using matscipy.elasticity.fit_elastic_constants() assuming cubic symmetry to reduce the number of calculations required.

from matscipy.elasticity import fit_elastic_constants

si = bulk(el, a=a0)

si.calc = calc

C, C_err = fit_elastic_constants(si, symmetry='cubic')

Fitting C_11

Strain array([-0.02, -0.01, 0. , 0.01, 0.02])

Stress array([-4.18432044e+00, -2.05307953e+00, 2.80518498e-05, 1.97564815e+00,

3.87438823e+00]) GPa

Cij (gradient) / GPa : 201.46145022444196

Error in Cij / GPa : 2.647085812210317

Correlation coefficient : 0.9997411341708425

Setting C11 (1) to 1.257423 +/- 0.016522

Fitting C_21

Strain array([-0.02, -0.01, 0. , 0.01, 0.02])

Stress array([-1.13681321e+00, -5.40617556e-01, 2.80518498e-05, 4.89094092e-01,

9.30337028e-01]) GPa

Cij (gradient) / GPa : 51.64012130007313

Error in Cij / GPa : 1.7644303539370763

Correlation coefficient : 0.9982534266024553

Setting C21 (7) to 0.322312 +/- 0.011013

Fitting C_31

Strain array([-0.02, -0.01, 0. , 0.01, 0.02])

Stress array([-1.13681321e+00, -5.40617556e-01, 2.80518498e-05, 4.89094092e-01,

9.30337028e-01]) GPa

Cij (gradient) / GPa : 51.640121300073226

Error in Cij / GPa : 1.7644303539370798

Correlation coefficient : 0.9982534266024553

Updating C31 (7) with value 0.322312 +/- 0.011013

Fitting C_44

Strain array([-0.02, -0.01, 0. , 0.01, 0.02])

Stress array([-2.43911452, -1.19994934, 0. , 1.16236258, 2.28858331]) GPa

Cij (gradient) / GPa : 118.17707578222974

Error in Cij / GPa : 1.285752118095864

Correlation coefficient : 0.9998224896716033

Setting C44 (4) to 0.737603 +/- 0.008025

[[b C11 b C12 b C12 b b b ]

[b C12 b C11 b C12 b b b ]

[b C12 b C12 b C11 b b b ]

[b b b b C44 b b ]

[b b b b b C44 b ]

[b b b b b b C44]]

=

[[201.46 51.64 51.64 0. 0. 0. ]

[ 51.64 201.46 51.64 0. 0. 0. ]

[ 51.64 51.64 201.46 0. 0. 0. ]

[ 0. 0. 0. 118.18 0. 0. ]

[ 0. 0. 0. 0. 118.18 0. ]

[ 0. 0. 0. 0. 0. 118.18]]

C_11 = 201.46 +/- 2.65 GPa

C_12 = 51.64 +/- 1.76 GPa

C_44 = 118.18 +/- 1.29 GPa

C_11 = C[0, 0] / units.GPa

C_12 = C[0, 1] / units.GPa

C_44 = C[3, 3] / units.GPa

We extract the cubic elastic constants \(C_{11}\), \(C_{12}\) and \(C_{44}\) and convert to units of GPa:

(C_11, C_12, C_44)

(np.float64(201.46145022444196),

np.float64(51.640121300073176),

np.float64(118.17707578222974))

The remaining ingredient is the surface energy, which we can also compute on-the-fly

# UPDATE to import from here once `adapticecont` branch is merged.

# from matscipy.fracture_mechanics.clusters import find_surface_energy

def find_surface_energy(symbol,calc,a0,surface,size=(8,1,1),vacuum=10,fmax=0.0001,unit='0.1J/m^2'):

# Import required lattice builder

if surface.startswith('bcc'):

from ase.lattice.cubic import BodyCenteredCubic as lattice_builder

elif surface.startswith('fcc'):

from ase.lattice.cubic import FaceCenteredCubic as lattice_builder #untested

elif surface.startswith('diamond'):

from ase.lattice.cubic import Diamond as lattice_builder #untested

## Append other lattice builders here

else:

print('Error: Unsupported lattice ordering.')

# Set orthogonal directions for cell axes

if surface.endswith('100'):

directions=[[1,0,0], [0,1,0], [0,0,1]] #tested for bcc

elif surface.endswith('110'):

directions=[[1,1,0], [-1,1,0], [0,0,1]] #tested for bcc

elif surface.endswith('111'):

directions=[[1,1,1], [-2,1,1],[0,-1,1]] #tested for bcc

## Append other cell axis options here

else:

print('Error: Unsupported surface orientation.')

# Make bulk and slab with same number of atoms (size)

bulk = lattice_builder(directions=directions, size=size, symbol=symbol, latticeconstant=a0, pbc=(1,1,1))

cell = bulk.get_cell() ; cell[0,:] *=2 # vacuum along x axis (surface normal)

slab = bulk.copy() ; slab.set_cell(cell)

# Optimize the geometries

from ase.optimize import LBFGSLineSearch

bulk.calc = calc ; opt_bulk = LBFGSLineSearch(bulk) ; opt_bulk.run(fmax=fmax)

slab.calc = calc ; opt_slab = LBFGSLineSearch(slab) ; opt_slab.run(fmax=fmax)

# Find surface energy

import numpy as np

Ebulk = bulk.get_potential_energy() ; Eslab = slab.get_potential_energy()

area = np.linalg.norm(np.cross(slab.get_cell()[1,:],slab.get_cell()[2,:]))

gamma_ase = (Eslab - Ebulk)/(2*area)

# Convert to required units

if unit == 'ASE':

return [gamma_ase,'ase_units']

else:

from ase import units

gamma_SI = (gamma_ase / units.J ) * (units.m)**2

if unit =='J/m^2':

return [gamma_SI,'J/m^2']

elif unit == '0.1J/m^2':

return [10*gamma_SI,'0.1J/m^2'] # units required for the fracture code

else:

print('Error: Unsupported unit of surface energy.')

surface_energy, unit = find_surface_energy(el, calc, a0, 'diamond111')

Step Time Energy fmax

LBFGSLineSearch: 0 21:33:12 -416.313600 0.000000

Step Time Energy fmax

LBFGSLineSearch: 0 21:33:12 -403.303800 0.000002

Build crack system

We now have all the material parameters needed and can proceed to define the crack system. Usually the contents of the cell below (together with the code above to compute the elastic constants and surface energy) would be included in a file named params.py which would then be imported by the scripts in matscipy/fracture_mechanics/scripts, e.g. the quasistatic_crack.py script on which this tutorial is based.

n = [ 4, 4, 1 ]

crack_surface = [ 1, 1, 1 ]

crack_front = [ 1, -1, 0 ]

crack_tip = [ 41, 56 ]

skin_x, skin_y = 1, 1

vacuum = 6.0

fmax = 0.05

# Setup crack system

cryst = diamond(el, a0, n, crack_surface, crack_front)

set_groups(cryst, n, skin_x, skin_y)

ase.io.write('cryst.cfg', cryst)

# Compute crack tip position

r0 = np.sum(cryst.get_positions()[crack_tip,:], axis=0)/len(crack_tip)

tip_x0, tip_y0, tip_z0 = r0

skin_x = 1*a0, skin_y = 1*a0

skin_x = 6.651528501120585, skin_y = 9.406681816795917

We can now visualise the crystall unit cell:

show_ase(cryst)

We define a CubicCrystalCrack object to represent our crack system. This takes the crystal orientations and the elastic constants (either as three cubic constant as we do here, or as a full 6x6 stiffness matrix in either the crystal reference frame or rotated to the specimen frame).

crk = CubicCrystalCrack(crack_surface, crack_front,

C_11, C_12, C_44)

By providing the surface energy, the crk object can be used to compute the Griffith estimate of the critical stress intensity factor at which fracture becomes thermodynamically favourable.

k1g = crk.k1g(surface_energy)

k1g

138.28375130769052

Apply initial strain field

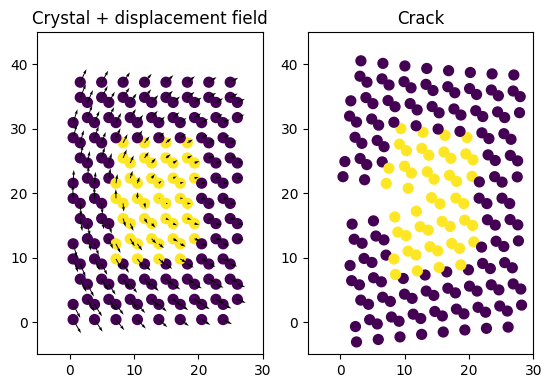

We have everything we need to apply the continuum linear elastic displacement field to our crystal. We centred the field on the middle of the cryst structure.

tip_x = cryst.cell.diagonal()[0]/2

tip_y = cryst.cell.diagonal()[1]/2

crack = cryst.copy()

crack.set_pbc([False, False, True])

k1 = 1.0

ux, uy = crk.displacements(cryst.positions[:,0], cryst.positions[:,1],

tip_x, tip_y, k1*k1g)

crack.positions[:, 0] += ux

crack.positions[:, 1] += uy

# Center notched configuration in simulation cell and ensure enough vacuum.

oldr = crack[0].position.copy()

crack.center(vacuum=vacuum, axis=0)

crack.center(vacuum=vacuum, axis=1)

tip_x += crack[0].x - oldr[0]

tip_y += crack[0].y - oldr[1]

show_ase(crack)

import matplotlib.pyplot as plt

fig, (ax1, ax2) = plt.subplots(1, 2)

ax1.scatter(cryst.positions[:,0], cryst.positions[:,1], s=50, c=cryst.arrays['groups'])

ax1.quiver(cryst.positions[:,0], cryst.positions[:,1], ux, uy)

ax2.scatter(cryst.positions[:,0] + ux, cryst.positions[:,1] + uy, s=50, c=cryst.arrays['groups'])

ax1.set_title('Crystal + displacement field')

ax2.set_title('Crack')

for ax in [ax1, ax2]:

ax.set_aspect('equal')

# ax.set_xticks([])

# ax.set_yticks([])

ax.set_xlim(-5, 30)

ax.set_ylim(-5, 45)

pass